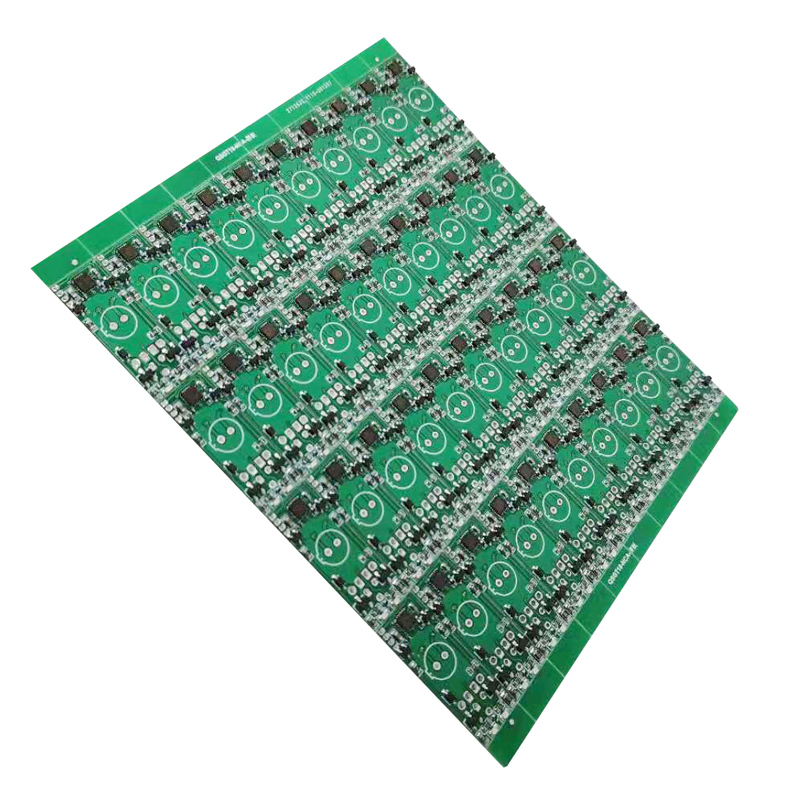

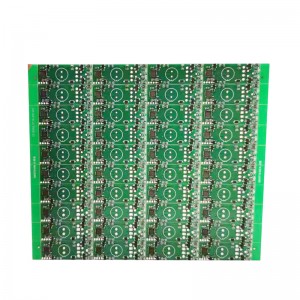

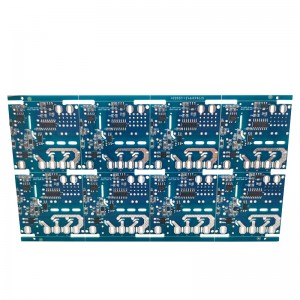

Provide One-Stop Pcb Prototype SMD Manufactur Assembly SMT Patch Processing Solution

Quality Control

ISO9001 Quality Management

100% incoming Inspection by IQC;

100% AOI inspection for Inner layer ;

Copper thickness measured by OXFORD;

Control line width/trace during etching;

Gold thickness measured by X-ray;

100% E-test to certify zero short/open circuit;

IPC-A-600G Quality standard for acceptance;

Certificated rating 94v0

About us

Why choose us?

Wenzhou LMO Electrical Appliance Co., Ltd. was established in April 2014 with a clean factory of about 4000sq.m. After years’ growth, nowadays we have several experienced & strong technicians and advanced SMT & DIP &test equipment, like high-speed SMT machine, wave-soldering machine, AOI inspection instrument and so on. At present, we could provide these services, components sourcing, project design, SMT Chip processing, DIP, components assembly and soldering, finished products assembly, housing structure design and mold opening etc. Until now, we own excellent product design & advanced manufacturing technology, stable quality performance and perfect management system. Therefore, we could provide professional and efficient one-stop services for customers all over the world. Looking forward to working with you based on win-win principle!

product specification

|

SMT Manufacturing Capability |

|||

| Item | Manufacturing Capability in process | Manufacturing Method | |

| Production size(Min/Max) | 50×50mm / 500×500mm | ||

| Production board thickness | 0.2~4mm | ||

| Printing solder paste | Support method | Magnetism fixture, vacuo platform | |

| Clamping method | Sticking up by vacuo, clamping on both sides ,flexible clamping with sheet, flexible clamping with thick board | ||

| Cleaning Method of printing solder paste | Dry method wetting method in Vacuo method | ||

| Accuracy of printing | ±0.025mm | ||

| SPI | Repeated accuracy of volume | <1% at 3σ | |

| Mounting component | Components size | 0603(Option) L75mm Connector | |

| Pitch | 0.15mm | ||

| Repeated accuracy | ±0.01mm | ||

| AOI | FOV size | 61×45mm | |

| Test speed | 9150mm²/Sec | ||

| 3D X-ray | Shootingangle | 0-45 | |